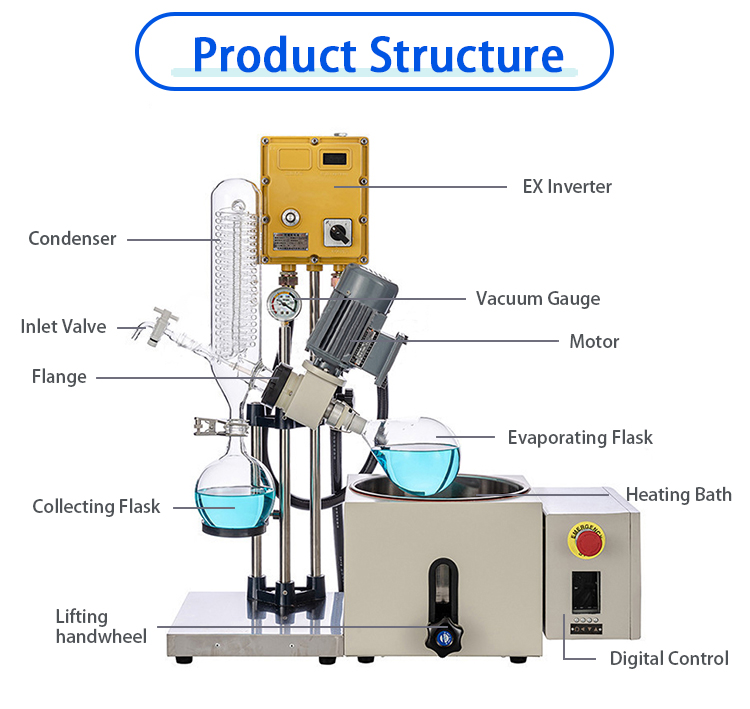

DESCRIPTION

The explosion-proof rotary evaporator is mainly used for concentration, crystallization, drying, separation and solvent recovery in the pharmaceutical, chemical and biopharmaceutical industries. The principle is to heat the rotating bottle at a constant speed under vacuum conditions, and the material forms a large-area film on the bottle wall, which evaporates efficiently. The solvent vapor is cooled by a high-efficiency glass condenser and recovered in the collection bottle, which greatly improves the evaporation efficiency. It is especially suitable for the concentration and purification of biological products that are easily decomposed and denatured at high temperature.

FEATURES

1. All of the high boric silicon glass (expansion coefficient 3.3) and polytetrafluoride material are all used in contact with the material contact portion, and the performance is stable, and it is not easy to chemically react with materials.

2. The main bracket uses cold plate anti-corrosion spray + aluminum alloy material, and has strong anti-corrosion characteristics. Pot bile adopts stainless steel quality, compact structure, durable, beautiful appearance;

3. The sealing system uses the polytetrafluoroethylene + fluororubber combination seal to maintain high vacuum;

4. Vacuum pressure gauge display real-time vacuum, pointer display;

5. The piston feeding valve sleeve piratifores lengthen tubes, which can be continuously fed to evaporation bottles in a vacuum state, which is convenient for customers.

6. Integrated condenser, upright double-layer snake-shaped coil to ensure high recovery;

7. Variable frequency speed, explosion-proof switch. The knob is fine-tuning, the number of revolutions is displayed;

8. Constant temperature bath temperature digital display, K-type sensor + stainless steel probe, fast transmission temperature

9. Bath pot hand wheel rises, easy to operate;

10. Electric explosion-proof, variable frequency speed aluminum shell explosion-proof, control plate aluminum shell explosion-proof, cable wear explosion pipe.

SPECIFICATIONS

| Model | OQT-201EX | OQT-301EX | OQT-501EX |

| Voltage/Frequency | 220V/50HZ | 220V/50HZ | 220V/50HZ |

| Whole power | 1040W | 2040W | 2040W |

| Rotary power | EX40W | EX40W | EX40W |

| Heating power | 1000W | 2000W | 2000W |

| Vacuum degree | 0.0098Mpa | 0.0098Mpa | 0.0098Mpa |

| Rotary flask volume | eggplant shape 1L,Φ131mm/24# standard port | 3L,Φ195mm/Φ50 flange port | 5L,Φ230mm/Φ50 flange port |

| Receiving flask volume | round shape 1L,Φ131mm/35# ball mill port | 2L,Φ166mm/35# ball mill port | 3L,Φ195mm/上35# ball mill port,down with DN20 screw port |

| Rotary speed | 0-120rpm/min | 0-120rpm/min | 0-120rpm/min |

| Temp.cotrolling range | room temperature-180℃ | room temperature -180℃ | room temperature -180℃ |

| Temp. accuracy | ±1℃ | ±1℃ | ±1℃ |

| Flask lifting distance | 200mm | 200mm | 200mm |

| Condenser size | Φ85*430H(mm) ,down with 35# ball mill port | Φ100*530H(mm) ,down with 35# ball mill port | Φ100*530H(mm) ,down with 35# ball mill port |

| Condensation area | 0.17㎡ | 0.26㎡ | 0.26㎡ |

| Charging valve | 19# standard plug valve,feed nozzle (Pagoda-shape connectors), outer diameter 10mm | 19# standard plug valve,feed nozzle (Pagoda-shape connectors), outer diameter 10mm | 19# standard plug valve,feed nozzle (Pagoda-shape connectors), outer diameter 10mm |

| Vacuum suction nozzle | Pagoda-shape connectors, outer diameter 10mm | Pagoda-shape connectors, outer diameter 10mm | Pagoda-shape connectors, outer diameter 10mm |

| Condensing coil in and out circuation nozzle | Pagoda-shape connectors, outer diameter 12mm | Pagoda-shape connectors, outer diameter 12mm | Pagoda-shape connectors, outer diameter 12mm |

| Baiting valve | / | / | Side discharging nozzle (pagoda-shape connectors), outer diameter 15mm, 200 from the floor |

| Pot bravery size | Φ245*140H(mm) about 6.6L,5.5kg | Φ265*160H(mm) about 8.8L,7.3kg | Φ280*170H(mm) about 10.4L, 13kg |

| Overall dimensions (W*L*H) | 750*360*1060mm | 790*360*1090mm | 790*360*1090mm |

| Net weight | 32kg | 33kg | 34kg |

| Packing dimensions | 900*620*470mm, 0.29m³ | 1090*690*490mm 0.37m³ | 1090*690*490mm, 0.37m³ |

| Packing weight | 49kg | 50kg | 51kg |

APPLICATION

- Chemical Laboratories

- Pharmaceutical Industry

- Essential Oil Extraction

- Cannabis Industry

- Food and Beverage Industry

- Environmental Analysis

- Academic Research

WHY CHOOSE US

- Factory direct sales with competitive price.

- Premium quality with CE & ISO certification.

- Strong product OEM & ODM customization capability.

- Promise production & on-time delivery.

- Perfect after-sales service, free product accessories.

- 15 years of experience in R&D and production of centrifugal extractor machine.

OUR FACTORY

We have a standard production workshop and a complete production team. They always produce a serious and responsible attitude to produce each product. Our R&D team is made up of multi-aspects professional engineers such as design engineer,technology specialist ,qualified specialist and process control manager, etc. Our qualified specialists strictly realize the process comprehensive supervision based on our quality process control system, which contains products design, research and development, test, production, quality inspection and packaging.

PACKAGING & SHIPPING

Our product packaging has been proven over the long term and we usually have plywood boxes or cartons with trays. We will arrange the appropriate packaging according to the weight and size of the goods. Of course, you can also choose the packaging form.

CUSTOMER CASES

Our laboratory instruments and equipment are used in many scientific laboratories, scientific research institutions, universities, hospitals, centers for disease control and other institutions, and are combined with many well-known biopharmaceuticals, new energy, electronics companies, food processing, environmental protection, etc. Enterprise cooperation, our stable and reliable products are exported to more than 120 countries around the world, and have been highly recognized by them, believe OQTSUPPLIES, we grow together!