5 Advantages OQT Stainless Steel Reactor

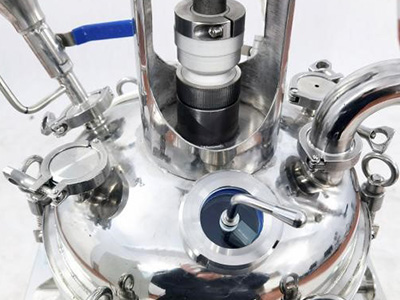

- 1. Multi -mouth reaction kettle cover, the number of kettle mouth can be customized, and the large -mouth design is easy to clean.

- 2. Visualized glass window, you can see the reaction in the kettle body.

- 3. Stainless steel graphite combination mechanical sealing has wear resistance, high temperature resistance, and better sealing.

- 4. Vacuum pressure gauge real-time pointer display real vacuum.

- 5. Standard stainless steel miles, stable connection, strong sealing.

DESCRIPTION

The Double layer stainless steel reactor is designed with double-layer stainless steel. The reaction solvent is placed in the inner layer for stirring reaction, and the interlayer can be connected to different cold and heat sources (refrigeration liquid, hot water or hot oil) for cyclic heating or cooling reaction. Under set constant temperature conditions, in a closed stainless steel reactor, the stirring reaction can be carried out under normal pressure or negative pressure according to the use requirements, and the reaction solution can be refluxed and distilled. It is an ideal choice for modern fine chemical plants, biopharmaceuticals and Ideal pilot and production equipment for the synthesis of new materials.

FEATURES

1. Frequency conversion speed regulation, AC induction motor. The speed is constant, no brushes, no sparks, safe and stable, and can work continuously.

2. The entire set of instruments is made of SUS316L/SUS304 stainless steel, which has good chemical and physical properties.

3. The mezzanine interface is connected with hot oil for circulation and heating reaction can be carried out, and the refrigerant liquid is connected with it for low-temperature reaction.

4. It can react at room temperature, and the reaction heat can be quickly taken away by running tap water on it.

5. The lower discharge port uses a stainless steel ball valve. There is no dead space in the container and it is removable to facilitate the discharge of solid materials.

6. Eight-port reactor cover, extra-large port design for easy cleaning, standard port socket for optional assembly of reflux and distillation synthesis devices.

SPECIFICATIONS

| Model | OQT-30L |

| Kettle volume | 30L |

| Mezzanine volume | 8L |

| Voltage/frequency | 220V/50 Hz |

| Reaction temperature | -120~260℃ |

| Pressure | -0.1~0.3Mpa |

| Stirring speed | 0-460rpm |

| Power | 200W |

| Sealed form | Stainless steel graphite combination mechanical seal |

| Number of cauldron lid openings | Eight ports (optional) |

| Material | SUS316L/SUS304 |

| Sight glass | Φ32 |

| Scraper sight glass | Φ51 |

| Temperature measuring hole | 50.5 chuck/Φ12 temperature measuring tube |

| Return hole | 50.5 chuck/1000ml funnel |

| Drop hole | 50.5 chuck/Φ38 return port |

| Pressure gauge | 50.5 chuck/± integrated pressure gauge |

| Impeller | SUS316L propeller mixing paddle |

| Condenser | 50.5 chuck/φ89 column cooling |

| Exhaust | 2-point exhaust valve |

| Bottom valve | 50.5 chuck/Φ89 column cooling |

| Overall dimensions | 530*530*1900mm |

| Optional(Additional fee) | Explosion-proof whole machine/

electric heating/full 316L/collection tank/ mobile frame /spraying PTFE |

APPLICATION

- Chemical Synthesis

- Pharmaceutical Production

- Petrochemical Industry

- Material Science

- Food and Beverage Industry

- Environmental Analysis

- Academic Research

- Biochemical Engineering

WHY CHOOSE US

- Factory direct sales with competitive price.

- Premium quality with CE & ISO certification.

- Strong product OEM & ODM customization capability.

- Promise production & on-time delivery.

- Perfect after-sales service, free product accessories.

- 15 years of experience in R&D and production of centrifugal extractor machine.

OUR FACTORY

We have a standard production workshop and a complete production team. They always produce a serious and responsible attitude to produce each product. Our R&D team is made up of multi-aspects professional engineers such as design engineer,technology specialist ,qualified specialist and process control manager, etc. Our qualified specialists strictly realize the process comprehensive supervision based on our quality process control system, which contains products design, research and development, test, production, quality inspection and packaging.

PACKAGING & SHIPPING

Our product packaging has been proven over the long term and we usually have plywood boxes or cartons with trays. We will arrange the appropriate packaging according to the weight and size of the goods. Of course, you can also choose the packaging form.

CUSTOMER CASES

Our laboratory instruments and equipment are used in many scientific laboratories, scientific research institutions, universities, hospitals, centers for disease control and other institutions, and are combined with many well-known biopharmaceuticals, new energy, electronics companies, food processing, environmental protection, etc. Enterprise cooperation, our stable and reliable products are exported to more than 120 countries around the world, and have been highly recognized by them, believe OQTSUPPLIES, we grow together!